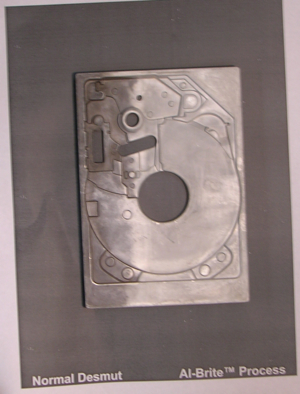

The Al-Brite™ Process for Desmut/Deoxidize of Aluminum Castings

The Al-Brite™ process was developed to de-smut and deoxidize aluminum castings completely, easily, and controllably. The Al-Brite™ process has revolutionized production and finishing of aluminum castings that must be oxide and particle-free for their end applications. Al-Brite™ process eliminates oxide and cleans parts to achieve previously unobtainable low particulate levels.Besides being effective and complete, the Al-Brite™ process stands out as being controllable and predictable. Process windows can easily be achieved and controlled. The Al-Brite™ process controls allow chemical usage until the bath has become excessively diluted and to bed out. Periodic additions of chemicals extend bath life, a key to reliable, cost effective and quality finishing.

The Al-Brite™ process has shown that it can make several standard process steps obsolete. It can in many cases make pre-etching and subsequent conversion coatings completely unnecessary, thus lowering production costs, while assuring consistent high quality finishes..

The Al-Brite™ process is a simple process that improves bath life and ease of operation. Long bath life minimizes waste treatment issues, which in-turn lowers the overall cost of ownership.

The Al-Brite™ process has improved yields and decreased costs in virtually all aluminum casting cleaning applications.

Recommended Al-Brite Process for Base Castings

Rinse Unheated for 45 Seconds

Rinse Unheated for 45 Seconds

Air Knife or Hold for Drain

Hold for Drain

Rinse Unheated Deionized for 20-30 Seconds. Agitation?

Rinse Unheated Deionized for 30-60 Seconds.

Dry Unheated Air Knife?

E-Coat

The Al-Brite™Process