Cleaning/Renewing Probes Is The First Step

When wafer probes become loaded with oxide, it is now feasible to clean/renew them to essentially as-new performance/conductivity levels. This is done using agents which convert the Aluminum and Copper oxide into soluble forms, which dissolve readily in the cleaner. However, the process of cleaning/renewing inevitably leaves the probe completely unprotected by any oxide layer, and thus prone to rapid/heavy tarnishing. Unless this propensity to tarnishing is curbed, it will result in contact resistance building rapidly.This re-oxidation can be avoided by including in the cleaner/renewing chemistry an organic anti-tarnish agent, which, properly chosen, protects the probe surface, without interfering with conductivity. Key words in the previous are “properly chosen”, as the commonly known anti-tarnish agents (Triazoles and imidazoles) give thick multilayer coats, known to increase contact resistance.

What is needed is an agent which will react with the surface metal, and leave an insoluble mono-molecular coating, which reduces the potential of the surface metal to react with atmospheric Oxygen. This is no small feat, but has been achieved, and results in a probe which acts like a brand new probe,

The ProbeWash™ (RDZ-1730) approach removes oxides chemically, not by physical abrasion. Since there is no abrasion of the probe, the contact points are not degraded by the cleaning process, and the surface is left protected by the anti-tarnish, so re-tarnishing is essentially halted.

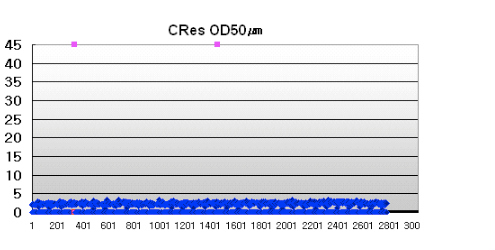

Contact Resistance on 50 μm probes BEFORE ProbeWash™ (RDZ-1730)

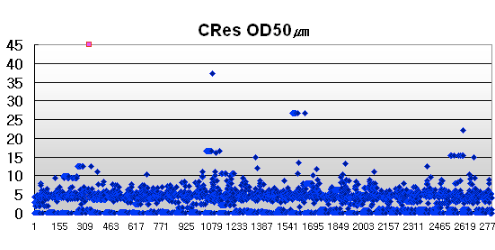

Contact Resistance on 50 μm probes AFTER ProbeWash™ (RDZ-1730)