Friday

Dec112009

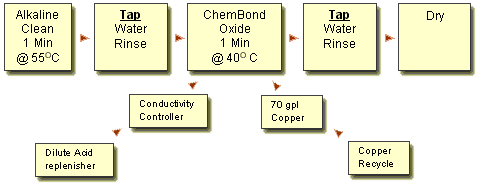

ChemBond™ EC process line

ChemBond EC Process Line:

Comparison Summary of Conventional vs. ChemBond™ EC

|

Per 1000 Ft2 of PCB

Innerlayer |

Conventional Oxide

|

ChemBond™ EC

|

|

Gallons Spent Solution

|

40

|

10

|

|

Gallons Treated Solution

Returned to Environment |

40

|

10

|

|

Pounds Copper sent to landfill

|

10

|

0

|

|

Pounds Copper recycled

|

0

|

10

|

|

Gallons Water

Required to be Deionized |

500-1000

|

0

|

|

Est. Cost of Deionizing Water

|

$20.00 - $40.00

|

0

|

|

Pounds Dithiocarbamate

Required for Waste Treatment |

150 (Minimum)

|

0

|

|

Value Dithiocarbamate

Required for Waste Treatment |

$75.00 (Minimum)

|

0

|

ChemBond™ EC is both economically and environmentally advantageous over current technology. A patent has been applied for covering this technology on March 29, 2002 (USP Application #60\280,390).

The Next Step in Alternate Oxide

RD Chemical Company introduces ChemBond™ EC, the next generation alternate oxide. ChemBond EC is a single step process, after cleaning. It is a one minute process, thus allowing high line speed, without excessive equipment footprint. The process removes only 15-20 µinches of Copper, and produces a bond (on FR-4) of 6.75 + pounds/inch average.Deionized water rinses are NOT required at any point in the process, thus lowering processing costs, and potential downtime.

ChemBond EC uses air instead of Hydrogen Peroxide to microetch the Copper. This allows many improvements on the process. Copper loading is very high (70 grams/liter of Copper metal) which allows the spent oxide solution to be returned to Copper recyclers, like Phibrotech.

The use of air instead of Peroxide means that the bath is stable, and very easily controlled. The bath is run in a feed and bleed mode, and controlled by monitoring the conductivity of the sump, which is a measure of the acidity. This means that there is a single replenisher, which is controlled automatically.

The use of air instead of Peroxide, is partly why the cost per surface square foot is so much lower, but this is only part of the reason why the cost is lower. Disposal costs will go virtually to zero. Because the spent solution can be so highly loaded with Copper, the organic additives in the chemistry which promote good bonding are used over a much larger area, thus spreading the expense of these costly additives over a much larger area. The net result is an oxide which is easy to use and control, and which costs dramatically less than Peroxide based systems.

Share

Share